Drive the vehicle home and allow the brakes pads and rotors to cool for at least 15 minutes before using the brake system again.

Should i put ceramic brake pads on a cargo van.

Ceramics are great in the aspect of wearrate and stopping but go to do a simple pad change later and find the rotors are shoot because ceramic are a lot harder so thus alot harder on the rotors.

As the latest solution in the brake pads market ceramic pads are slowly becoming more and more popular with manufacturers.

My dealer says they use oem brakes and rotors and i should pay the extra 300 for their service.

One con of ceramic brake pads is the cost.

Finally studies have found that ceramic brake pads have a longer life span without ever sacrificing noise control rotor life or braking performance.

The brake pads chosen are the low tier mid tier and upper.

Unfortunately these can make brakes hiss or even grind a little as you slow down.

The first thing you need to decide is whether you re looking for ceramic vs.

For this reason basic rotors are usually only recommended for use with the diy or garage grade brake pads that are semi metallic or fully organic or with the economy grade ceramic offerings.

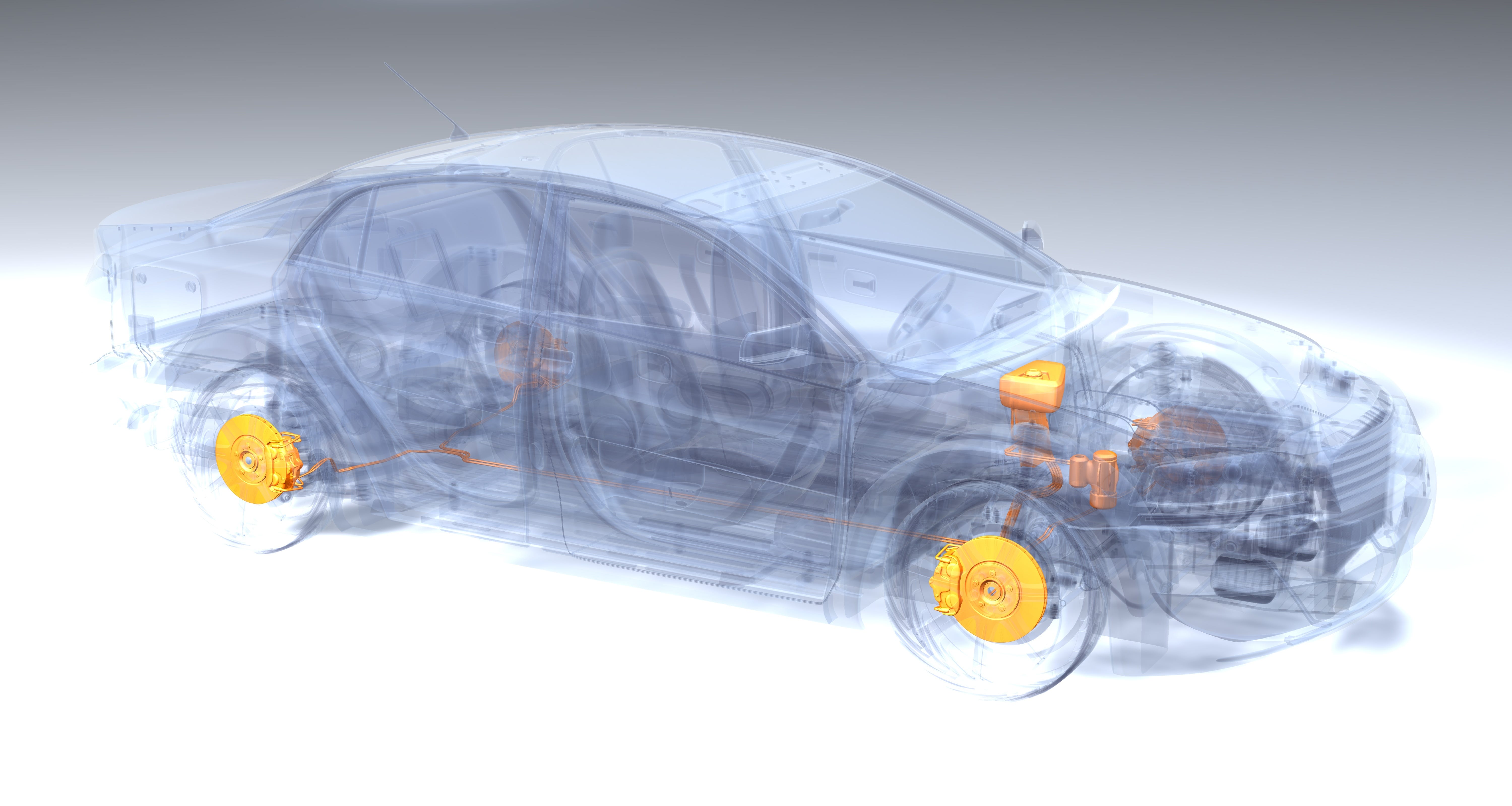

The ceramic compounds and copper fibers allow ceramic pads to handle higher brake temperatures with less heat fade provide faster recovery after the stop and generate less dust.

Each brake pad tested in this video came from different manufacturers but were made for the front brakes of the same model vehicle.

The need to slow down heavier cars led to the rise of metallics and ceramics in brake pads friction material.

My local mechanic says he can do the job for less and will use ceramic brake pads.

Constructed with ceramic fibers and an assortment of non ferrous fiber.

But while both semi metallic brake pads and ceramic brake pads or any brakes for that matter serve the same essential function there are a lot of differences between them.

Premium oe specification rotors are made from premium quality new steel to exacting tolerances.